Research and development at the highest level: thermofluids for electric vehicles

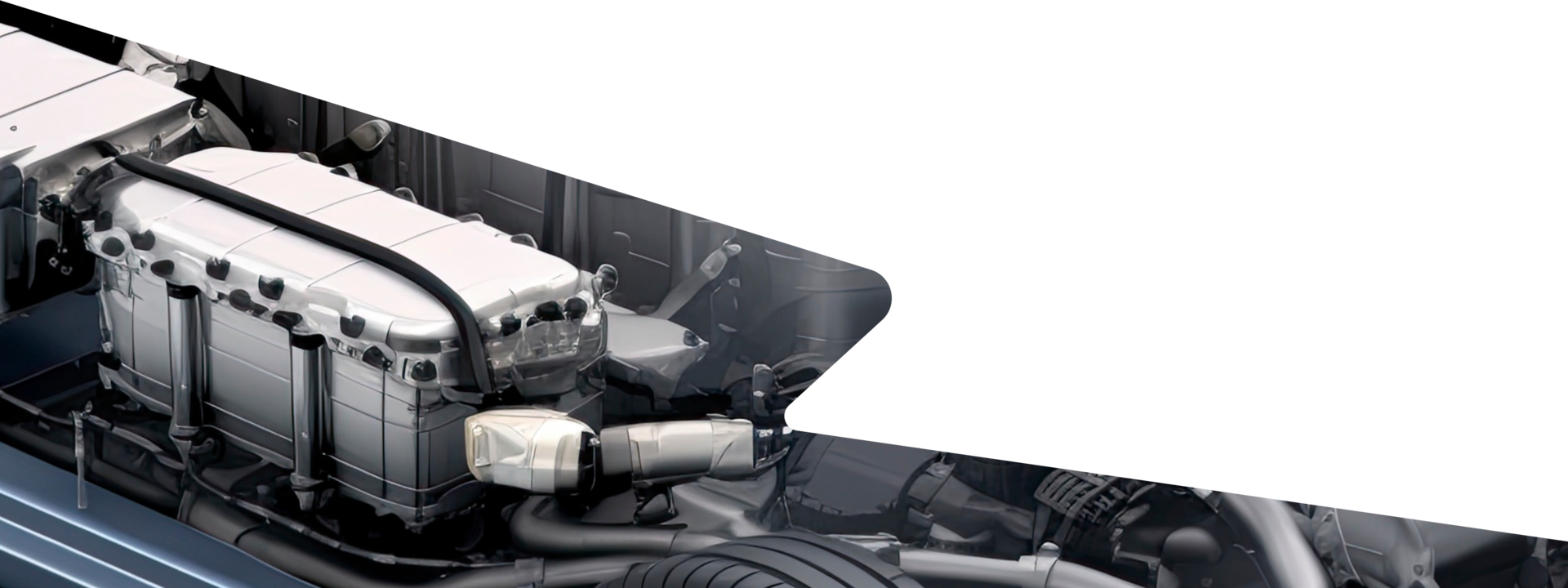

The market share of battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) is reporting constant growth. As demand has risen over the last several years, the requirements for ever greater ranges, performance, and fast-charging options have grown as well, which can only be implemented by means of battery concepts with higher and higher power densities, e.g. with lithium battery cells.

The increased heat generated in the batteries as a result requires sophisticated thermal management, which for safety reasons means prioritizing battery cooling more and more. The optimal temperature range for a lithium battery cell is between 15°C and 35°C. Outside of this temperature interval, unwanted side reactions can occur due to the temperature, which significantly reduces the service life of the cells (battery degradation).

Indirect and direct (immersion) battery cooling: what’s the difference?

In electric vehicles, there are two principal methods for battery cooling that keep the battery running within the optimal temperature range. Here are the differences between indirect and direct (immersion) battery cooling:

Indirect cooling

With indirect cooling, water-glycol mixtures are used as coolants for the battery, which is cooled by cooling plates as the coolant runs through the plates. When ambient temperatures and cooling performance are low, the heat can be discharged into the ambient air. When ambient temperatures are high, the heat can no longer be discharged into the air, but must be transferred to a coolant circuit.

Direct cooling (immersion cooling)

The idea behind immersion cooling (also known as liquid submersion cooling) is to put the electric components that need to be cooled in direct contact with a dielectric thermofluid. The battery cells are bathed directly by the electrically non-conducting/insulating fluid, which results in lower, homogeneous cell temperatures.

Our lab has extensive research and development infrastructure, as well as highly qualified experts who are capable of developing dielectric fluids for a number of applications, whether it be immersion cooling for batteries in electric cars, IT hardware, or electric components in other sectors.

immersion thermal management is fit for the future –

but challenging as well

The concept of immersion cooling offers three critical advantages over conventional

methods:

1. Prevents overheating – batteries charge and drain faster

2. Extends operating life

3. Expands the range

Because it comes into direct contact with a number of components and due to growing requirements for efficiency and environmental compatibility, these fluids must have complex characteristics. That’s why our fluids are thoroughly tested and validated according to international testing standards under ASTM or DIN to ensure that they meet the highest quality standards and provide optimal performance.

We use complex test benches and test profiles that allow us to put our fluids to the test under a variety of operating conditions so that we can evaluate and optimize their cooling performance. In this process, we work closely with research institutes and accredited test institutes.

In the course of our research activities, we have determined that our dielectric fluid, tested on two different test benches and in any of the operating conditions selected, exhibits better cooling performance than any other competing product used for battery cooling in electric vehicles.

Our approach: together with our customers and partners, we develop holistic, future-oriented solutions that cover both technical attributes as well as concerns of global marketing and logistics.

DO YOU HAVE ANY QUESTIONS?

Do not hesitate to contact us via our contact form.

العربية

العربية български

български Deutsch

Deutsch Ελληνικά

Ελληνικά English

English español

español français

français italiano

italiano Nederlands

Nederlands polski

polski português

português română

română Türkçe

Türkçe