THERMAL MANAGEMENT FOR YOUR REQUIREMENTS, IMMERSION COOLING AND INNOVATIVE COOLANTS.

Welcome to ROWE - your partner for customized coolants. Our innovative dielectric immersion fluids offer exceptional cooling performance, operational reliability, high material compatibility and outstanding corrosion protection. They impress with their oxidation stability and a wide range of viscosities that can be optimized depending on the application.

EFFICIENT COOLING

THROUGH MODERN TECHNOLOGIES.

Whether electromobility, data centers, supercomputers or industrial

industrial applications - our coolants guarantee maximum safety and durability. They ensure even and efficient heat dissipation, optimize temperature control and extend the service life of your systems. ROWE is your partner for advanced immersion cooling. With tailor-made solutions, we help to maximize cooling performance, minimize energy consumption and at the same time increase the reliability of your systems.

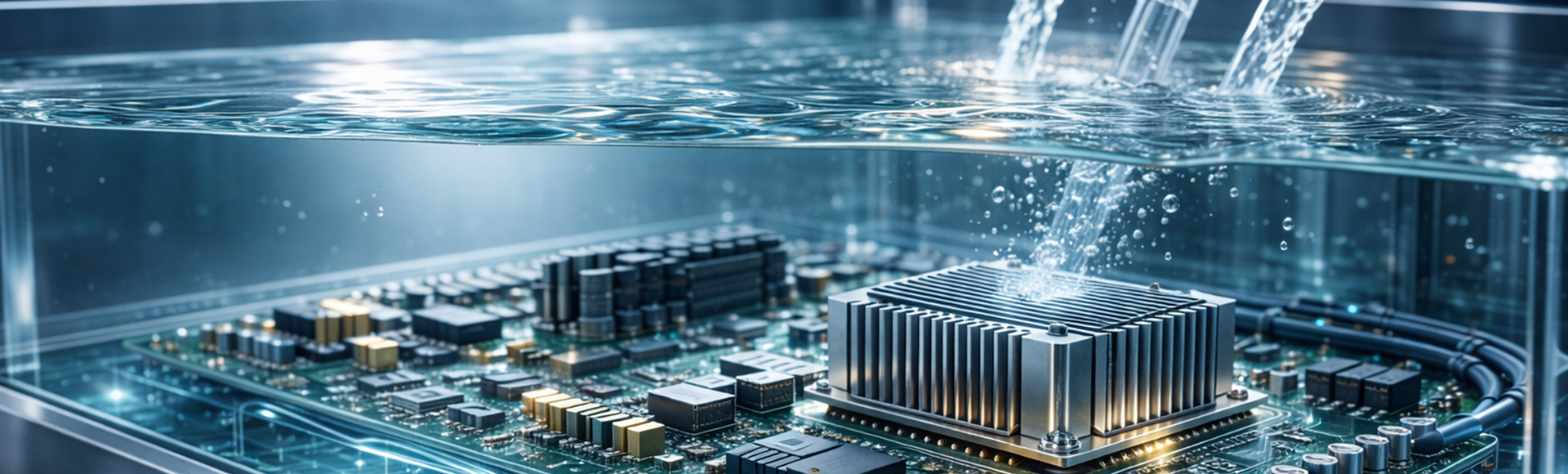

IMMERSION COOLING -

EFFICIENT COOLING FOR THE HIGHEST DEMANDS

Immersion cooling is an innovative technology in which electrical components are directly immersed in an electrically non-conductive cooling liquid. This method outperforms conventional air and liquid cooling as it enables uniform and efficient heat dissipation. Thanks to its high performance and energy efficiency, immersion cooling is particularly suitable for applications with high power density, such as data centers, electromobility and high-performance industrial systems.

ADVANTAGES OF IMMERSION COOLING COMPARED TO INDIRECT COOLING

Efficient heat dissipation

Uniform temperature control avoids hotspots

High energy efficiency

Reduced energy consumption due to the elimination of complex mechanical cooling systems

Low noise

No need for fans or pumps for quiet operation

Flexible applicability

Perfect for data centers, electromobility and industrial applications

Indirect cooling

With indirect cooling, water-glycol mixtures are used as coolants for the battery, which is cooled by cooling plates as the coolant runs through the plates. When ambient temperatures and cooling performance are low, the heat can be discharged into the ambient air. When ambient temperatures are high, the heat can no longer be discharged into the air, but must be transferred to a coolant circuit.

Direct cooling (immersion cooling)

The idea behind immersion cooling (also known as liquid submersion cooling) is to put the electric components that need to be cooled in direct contact with a dielectric thermofluid. The battery cells are bathed directly by the electrically non-conducting/insulating fluid, which results in lower, homogeneous cell temperatures.

Our lab has extensive research and development infrastructure, as well as highly qualified experts who are capable of developing dielectric fluids for a number of applications, whether it be immersion cooling for batteries in electric cars, IT hardware, or electric components in other sectors.

Benefits of our immersion cooling

- High thermal conductivity

For fast and efficient heat dissipation, ensuring optimum temperature control even at high power densities. - Excellent oxidation stability

Prevents thermal decomposition and ensures a long fluid life, even under demanding conditions. - Reliable material compatibility

Protects sensitive components from corrosion and ensures compatibility with metals, plastics and sealing materials.

- Low electrical conductivity

Ensures maximum safety in electrical

electrical applications. - Customizable viscosities

Depending on the area of application, the viscosity of our immersion fluids can be individually adapted to your requirements. - Excellent material compatibility

Extended service life of seals and electrical components.

IMPORTANT REQUIREMENTS FOR THE THERMOFLUIDS

PUBLICATIONS AND SCIENTIFIC PAPERS

Our coolants and technologies are presented in leading scientific journals and at conferences. Here we share the latest findings and research results on our products and their possible applications. Together with our scientific partners, we have published papers detailing the technical benefits and applications of our coolants. This work contributes to the advancement of cooling technology and strengthens our commitment to the progress of the industry. As part of our research, we have found that our dielectric fluids outperform most other competitor products used for cooling electrical components on two different test rigs, regardless of the operating conditions selected.

Areas of application for our immersion liquids

Our immersion fluids offer customized solutions for a wide range of applications. Discover how our cooling technologies can improve the efficiency and reliability of your systems.

Electromobility

Efficient cooling for

batteries

and electrical components

Data centers and

supercomputers

High performance

for optimum cooling

Electrical components, industrial applications & transformers

Innovative cooling technology for various industries

Our specialized laboratory is the heart of our research and development. Here we not only develop new coolants, but also adapt existing solutions to meet the specific requirements of our customers. We offer customized solutions that are perfectly tailored to your needs. Our team of highly qualified chemists and engineers analyze your requirements and develop coolants that are optimally adapted to the desired parameters such as flash point, viscosity, thermal conductivity and many other properties. We carry out a large number of tests in our laboratory. These are carried out in accordance with international test standards according to ASTM or DIN to ensure that they meet the highest quality standards.

Read now

FAQS -

FREQUENTLY ASKED QUESTIONS

START YOUR PROJECT WITH ROWE NOW!

Take advantage of our experience and customized solutions to meet your cooling requirements.